Metalenses are the future of optics. They are thin, light-weight, and can be manufactured at a fraction of the cost of traditional lenses. This blog post will discuss 10 amazing facts about metalenses that you need to know!

- Metalenses are thinner and lighter than traditional lenses.

Traditional lenses are typically made of glass or plastic and can weigh up to 100 grams. On the other hand, Metalenses weigh as little as a few milligrams! They are also much thinner than traditional lenses, making them ideal for portable devices like smartphones and tablets.

- Metalenses can be manufactured at a fraction of the cost of traditional lenses.

Manufacturing traditional lenses require expensive equipment and molds that can cost millions of dollars. In contrast, metalenses can be fabricated using simple lithography techniques widely used in the semiconductor industry. This makes them much more affordable to produce.

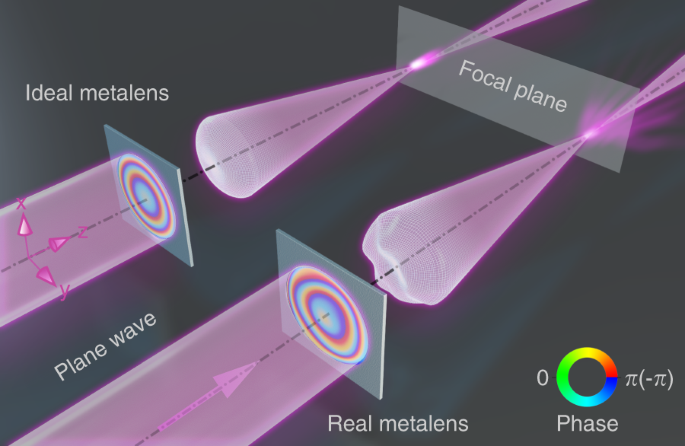

- Metalenses can be tuned to focus light in any direction.

Traditional lenses are limited in their ability to focus light. As a result, they can only direct light in a certain direction, leading to lost energy and reduced efficiency. On the other hand, Metalenses can be tuned to focus light in any direction. This means that they can capture more of the available light, leading to better performance and higher efficiency.

- Metalenses are not affected by temperature changes.

Temperature fluctuations often damage traditional lenses. The glass or plastic used to make them expands and contracts with changing temperatures, leading to cracking and other types of damage. Metalenses, however, is unaffected by temperature changes. This makes them ideal for applications where temperature fluctuations are common, such as in industrial and automotive settings.

- Metalenses can be used to create curved surfaces.

Traditional lenses can only be manufactured in a flat shape, which limits their ability to capture light from all directions. Metalenses can be fabricated into curved surfaces, allowing them to capture more light from all angles.

- Metalenses can correct optical aberrations.

Traditional lenses often produce optical aberrations, which are defects in the image that cause it to look blurry or distorted. Metalenses can be designed to correct these aberrations, leading to sharper and more accurate images.

- Metalenses are more durable than traditional lenses.

Traditional lenses can be easily damaged by scratches or impacts. Metalenses, on the other hand, are much more durable. This makes them ideal for applications where durability is a priority, such as in industrial and automotive settings.

- Metalenses can be used to create miniature optical systems.

Traditional lenses cannot be miniaturized because their size and weight limit their ability to focus light accurately. Metalenses, on the other hand, can be made very small and lightweight without sacrificing accuracy. This makes them perfect for use in miniature optical systems, such as cameras and microscopes.

- Metalenses have the potential to revolutionize the optical industry.

Traditional lenses have been around for centuries, and there is very little that can be done to improve their performance. Metalenses, on the other hand, are a relatively new technology and still have plenty of room for improvement. This means that they have the potential to revolutionize the optical industry in the years to come.

- Metalenses are only starting to be used in commercial applications.

Metalenses are still a relatively new technology, and most of them are being used in research and development applications. However, as more and more advances are made in this area, metalenses will likely start being used in commercial applications as well. Stay tuned!